Engineered in the UK - from design to production

Product Design

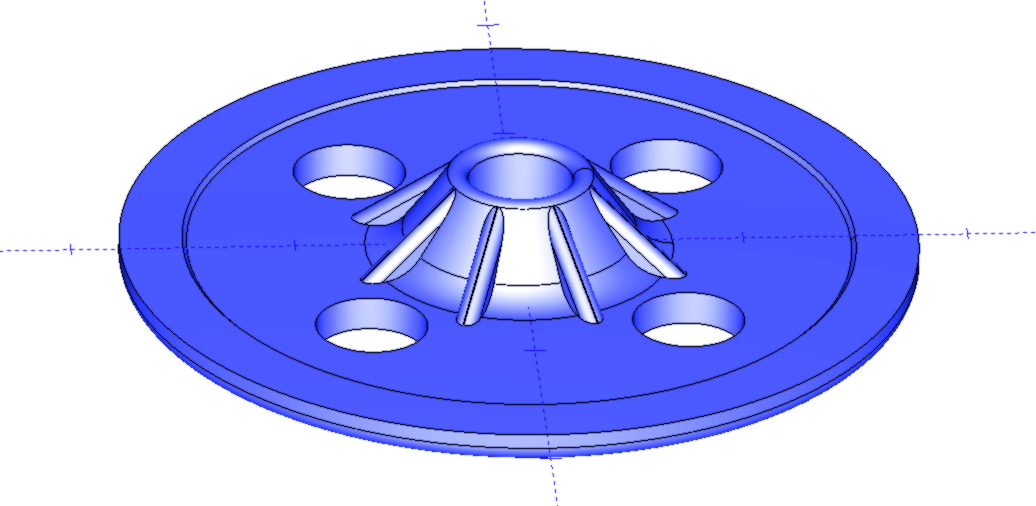

From an initial concept the part moves to a CAD/CAM product design and a computer generated 3D model. At this stage materials are considered as is the manufacturing process.

A mould base is then designed in order to manufacture the product. This might be a single cavity or multi-cavity tool complete with a parts ejection system and cooling/heating circuits as required.

Once the bolster has been designed then all of the individual mould plates and components required to build the tool can be acquired and the job passes to our tool room.

Once the bolster has been designed then all of the individual mould plates and components required to build the tool can be acquired and the job passes to our tool room.

Manufacturing the Mold

Manufacturing a plastic injection mould is a complicated and precise process, not only does the part form have to be machined into both the core and cavity plates but there is a requirement for pillars and posts in both halves, a spru bush or hot runner system to guide the melted plastic into the mould, heating/cooling circuits, location rings, insulation boards and an ejection system. Even a simple mould can require two to three weeks of machining.

An average sized steel plastic injection mould will weigh between 50 to 80kg once complete.

An average sized steel plastic injection mould will weigh between 50 to 80kg once complete.

Mould Testing - Pre Production

Once the mould has been completed it will need testing, this involves mounting it on one of our plastic injection moulding machines. Which machine was decided a lot earlier in the design phase as each machine has a different barrel capacity. Making a very small part on a large machine will always cause problems, it may take many shots for the melted plastic to move through a large injection barrel. In this case the melted plastic which can be as hot as 280 degrees C will have too much residency causing it to stress and also have a potential to burn. Likewise you can’t make a large part on a small machine as it won’t have the capacity required to fill the mould in one shot. We have 6 plastic injection moulding machines from 35 to 90 tons, this is the clamping force generated on the mould during the injection phase.

Part Production

At this stage we are ready to make the part for the first time, there are many factors at play here, getting the material quantities and processing conditions correctly setup! Will the product eject from the machine correctly? And of course is the product as designed and suitable for use?

It is purely experience that allows us to get this right first time but quite often a new mould will need further minor modifications in the tool room before it can finally be signed off for production.

Product Testing

Product testing is a very important part of the production process for ourselves, a designed product may look okay but when it is actually used in the real world it may have severe failings, some times this can be fixed by making it from a different polymer but many times it will mean a change to the design and a modifications to the mould.

All the above we do in house, nothing is sub contracted out and being able to complete this whole process ourselves means we can adapt quickly and control the quality and suitability of everything that we manufacture.

-150x150.jpg)